Remapping Logistics Supply Chains: Tomato Edition

Written by

Vivek V.S

Vignesh Balaji NV

Anvesh Dyava

Background:

For the past 1 year, we have supplied 1000 tonnes of Onion for the customers of Subjimandi.app . First, we traced the norms and patterns of the existing supply chain. With our learnings, we defined our own supply chain from production regions(farmers) to consumption regions (buyers). Last month, Subjimandi ventured into Tomatoes. We worked very closely with them to re-define logistics supply chain for tomatoes.

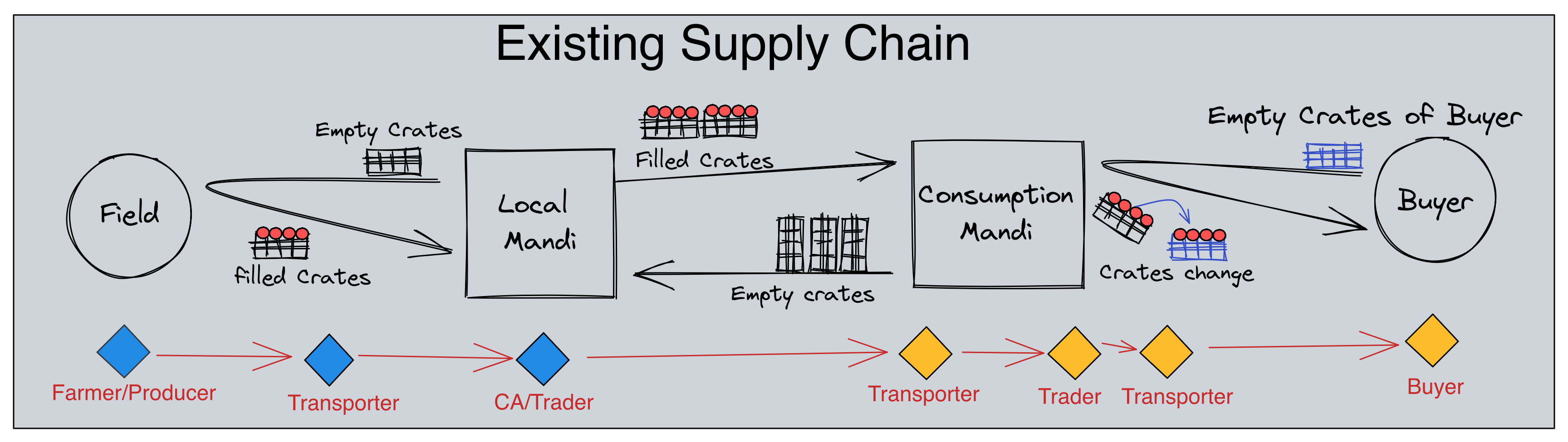

Existing Supply Chain:

We spent a week understanding the existing supply chain. The key difference between Tomato and Onion is their packaging. Tomatoes are packaged into crates. The empty crates have to travel back.

In the best case scenario, there are about 7 participants in the Tomato supply chain.

- Farmer/Producer

- Local Mandi - Commission Agent/Trader

- Local Transporter ( First Mile )

- Mandi to Mandi Transporter (Long Haul Transporter )

- Consumption Mandi - Commission Agent/Trader

- Buyer at Consumption

- Transporter (Last Mile)

The second line above highlights the entities involved in the process.

Step 1: In the production region, empty crates move from the local mandi to the farm. Step 2: Crates are filled with tomatoes. They are sold at the local mandi. Step 3: The sold crates are taken to consumption regions by a inter mandi transportation truck. Step 4: In the consumption side, the buyer visits the mandi with empty crates. Step 5: After buying, they offloads the tomato to their own crates. Step 6: The empty crates from the consumption region are taken to the delivery regions within a day or two.

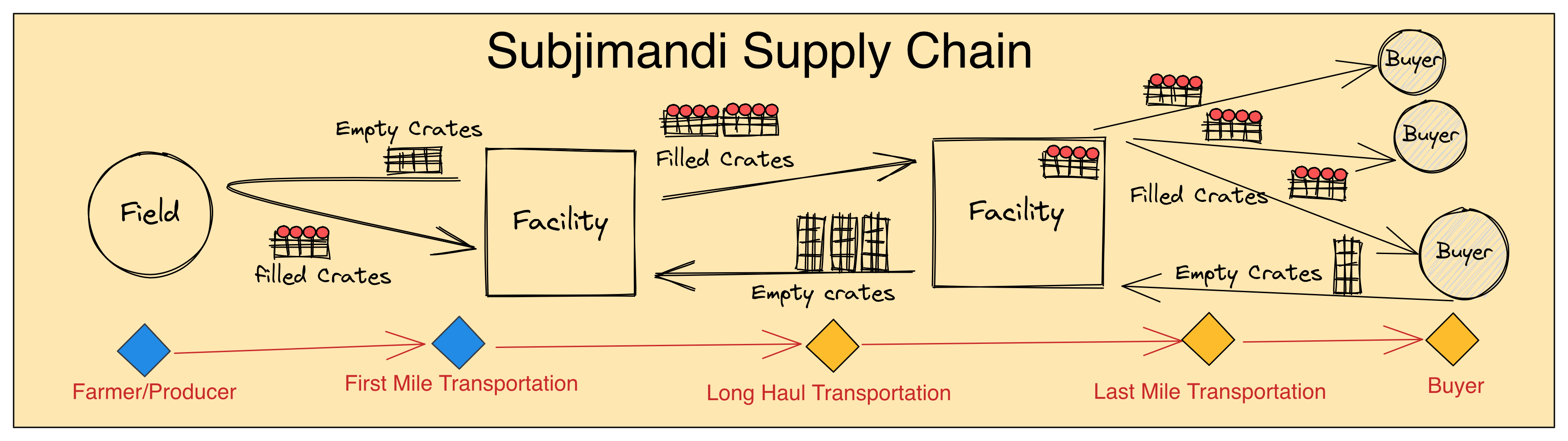

Tomato Supply Chain v1: Subjimandi

Similar to Onion, Subjimandi procures graded produce at the production region (Farm/Local Aggregation point) and directly serves to the buyer at consumption region. All the steps in this supply chain is undertaken by a single entity, Subjimandi. They deliver the crates to the buyer and collect empty crates back.

Pipehaul team facilitated the process using a slightly modified version of existing supply chain. Instead of Mandi, we were relying on existing warehouse facilities to move crates.

Issues with v1

Subjimandi is responsible for providing crates to either sides. The return logistics of crates with multi-aggregation and multi-distribution points is very complex. It also has multiple single point of failures to stop the process.

Few buyers didn’t have empty crates when we do the delivery. So a secondary trip for collecting crates was needed. We could not have defined times between drop off and pick up.

In our analysis, we were spending about 8% more than the existing supply chain to facilitate the trade for Subjimandi.app. Even with reduction of moves, optimisation of workflows and demand driven distribution, we end up spending more. This was taken as a strong proof that we need to work on reducing the movements further in order to provide cost effective logistics.

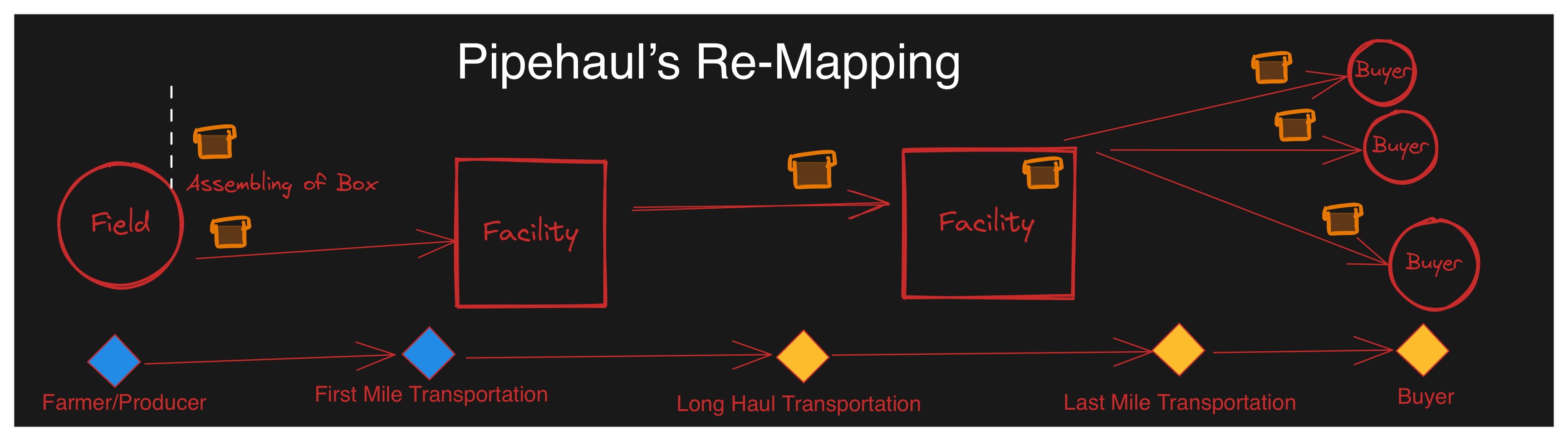

Tomato Supply Chain v2: Remapping

We decided to eliminate return logistics of empty crates. The solution is to switch to Corrugated Boxes (C.Boxes). The cost to facilitate the trade with C.Boxes helps us save 15% compared to existing supply chain.

However, this didn't include re-usable cost of crate vs one time use C.boxes. We believe C.boxes will add more cost on packaging. However if it is within 15% costs we saved by eliminating return logistics, we can shift Tomato supply chains into C.Boxes.

Removing empty crate return logistics reduces the complexity of the movements, avoids single point failure and increase cross utilisation of transportation. Instead of sending empty crates, we could utilise the time and space for moving other commodities.

This is some of the work we do at Pipehaul. Our ethos is to approach commodity supply chains as markets to enable cross commodity bundling, long-haul optimisation, decentralised aggregation and distribution in supply chains.

Follow up:

If you think, we have got something wrong. Please write to us at hello@pipehaul.com and let us know why? We would like to hear from other produce procurement companies why they continue to invest in crates when we are inclined on C.Boxes?

And if the problem we are solving is something you would like to do across multiple commodities with newer supply chain logistics processes and workflows. You can join us, we are hiring across roles and looking for interest aligned folks. Check out the open positions at the jobs board.